Steel is used in practically every aspect of life, including industries, homes, mining, fabrication, drilling, construction, bridges, and agriculture. Steel is one of the most popular metals because of its numerous advantages over other metals.

Refrigerators, hospital equipment, and protective footwear are all made of steel. Aside from these, structural steel has a number of other advantages. Structured steel can be both durable and re-usable.

Metal fabrication has progressed in leaps and bounds, and there are experts who can assist you. The primary attributes necessary while using machine structure fabrication Johor services are complete dedication to a good experience, quality, and state-of-the-art methods.

When looking for services, the most important features to look for are complete attention to cutting-edge methods, extensive expertise, and high quality.

Fabrication of metal and stainless steel is also utilized in:

- Steel erection drawings

- Structural steel design

- Steel pile foundation

- Steel metal design

- Steel metal drawings

- Steel foundation drawing and much more.

All of the following are critical in developing or erecting an efficient steel structure in a short period of time. As a result, structural steel manufacturing begins with a graphic depiction, which gives a concept of the prefabricated building components that will be employed in the construction. This helps you save a lot of time and money.

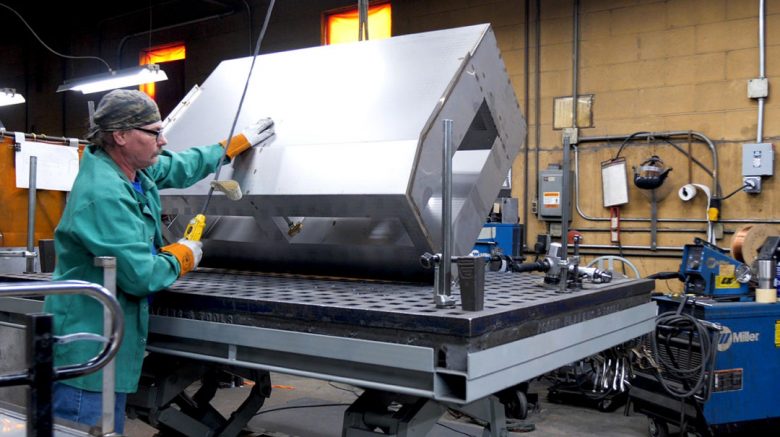

In general, structural engineers give services that are backed up by their extensive experience and commitment. Engineers first create steel structure designs before moving on to developing steel fabrications. The raw material is first reduced to the required size, and then the various sections are welded together to create the desired final product.

Plates, metal sheets, pipelines, and handrails are examples of steel fabrication elements. Finishing, surface cleaning, fitting and reaming, punching and drilling, cutting, machining, quality control, fastening, rolling, straightening, bending, and surface treatment are some of the common procedures used in structural steel production.

Any project will benefit from the structural manufactured steel framework for any construction or building. The collaboration materials will also be measured according to structural steel standards. As a result, the structural steel fabrication is first carried out using a graphic representation, which provides a concept of the prefabricated construction components that will be employed in the structure. This can help you save a lot of time and money.

By first producing steel structure designs and then assisting in the fabrication of steel fabrications, structural engineers give a variety of effective services combined with a unique experience.

Precautions must be taken to prevent the weldments from warping due to the heat. They could include re-designing weldments to use fewer welds, welding in stages, utilizing a heavy fixture to shield the weldments from the sun while cooling, and straightening the processes after welding.

Straightening twisted steel weldments with oxy-acetylene torches are akin to a form of art. Heat is applied to steel in a steady, linear sweeping motion. During the cooling time, the steel will have net contractions in the direction of the sweep.