GI (Galvanized Iron) pipe fittings are vital components of plumbing and industrial systems. In Malaysia, these fittings are widely used in various applications due to their durability, corrosion resistance, and cost-effectiveness. This comprehensive guide will provide valuable insights into GI pipe fittings Malaysia, including what they are, why they are essential, and how to use them effectively.

What are GI Pipe Fittings?

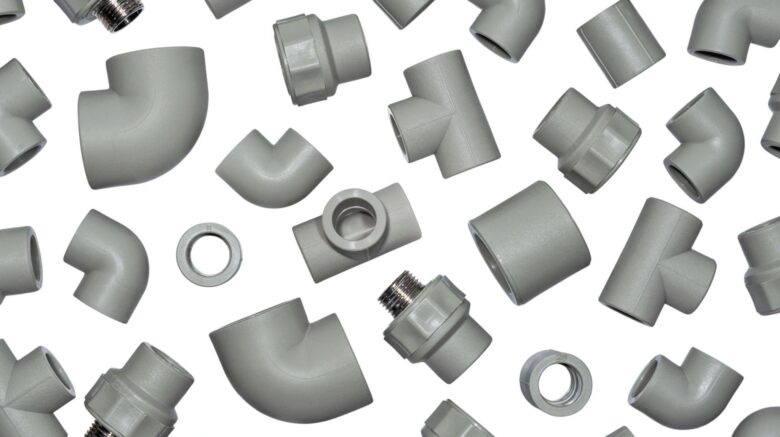

GI pipe fittings refer to a range of components used to connect and control the flow of galvanized iron pipes. These fittings are made from galvanized steel, which is coated with a layer of zinc to protect against corrosion. Common types of GI pipe fittings include elbows, tees, couplings, unions, reducers, and flanges. These fittings are available in different sizes and shapes to accommodate various plumbing and industrial requirements.

Why are GI Pipe Fittings Essential?

Durability and Corrosion Resistance: The galvanized coating on GI pipe fittings provides excellent resistance to rust and corrosion. This makes them ideal for installations in both indoor and outdoor environments, including plumbing systems, irrigation systems, and industrial applications.

Cost-Effectiveness: GI pipe fittings are relatively more affordable compared to other materials like stainless steel. Their long lifespan and low maintenance requirements contribute to their cost-effectiveness, making them a popular choice for plumbing projects in Malaysia.

Versatility: GI pipe fittings can be used in a wide range of applications, including water supply networks, sewage systems, gas pipelines, and fire sprinkler systems. Their versatility makes them suitable for both residential and commercial projects.

How to Use GI Pipe Fittings Effectively

Planning and Measurement: Before starting any installation, carefully plan and measure the pipe layout. Consider factors such as pipe diameter, length, and required fittings. Accurate measurements ensure proper fitting selection and minimize the risk of leaks or inefficient flow.

Proper Installation Techniques: Ensure that the pipes are cut accurately and deburred to prevent any obstructions or irregularities. Apply sealants or joint compounds to enhance the watertightness of the fittings. Use appropriate tools such as pipe wrenches and thread seal tapes to securely tighten the fittings.

Regular Maintenance: Conduct periodic inspections to identify any signs of corrosion or leaks. Promptly replace any damaged or worn-out fittings to maintain the integrity of the system. Regular maintenance extends the lifespan of the GI pipe fittings and ensures optimal performance.

Conclusion

GI pipe fittings play a vital role in plumbing and industrial systems throughout Malaysia. Their durability, corrosion resistance, cost-effectiveness, and versatility make them a popular choice among professionals and homeowners alike. Understanding what GI pipe fittings are, why they are essential, and how to use them effectively is crucial for anyone involved in plumbing or industrial projects. By following proper installation techniques and conducting regular maintenance, Malaysians can ensure the longevity and efficiency of their GI pipe fittings, making them an excellent investment for the long term.